DRYTILING

The Express Tile

Advantages

DRYTILING

Exactly positioned thanks to cork backing

Exactly positioned thanks to cork backingThe ceramic tiles, which are equipped with a 2.0 mm cork backing, are simply laid next to each other – without adhesive – and find their exact position due to the 1.5 mm all-round overlap of the cork backing. The resulting 3 mm wide joint between the tiles can be grouted immediately with a dispersion grout.

Quick installation

Quick installationLICO DryTiling has not only considerably simplified the process of laying tiles, but also speeded it up enormously. The easy and ergonomic laying of even large tile formats leads to a multiplication of the area output compared to classic tile laying with adhesive.

Easy to dismantle

Easy to dismantleCeramic tiles are extremely durable and long-lasting. But when their visual appearance is no longer fulfilling its purpose, or the lease expires, they need to be replaced. DryTiling tiles allow for quick and easy replacement without damaging the substrate.

Silent and warm to the feet

Silent and warm to the feetThe combination of the tile with the cork backing combines the advantages of both materials. While the tile provides robustness and ease of maintenance, the cork brings warmth and reduces impact sound.

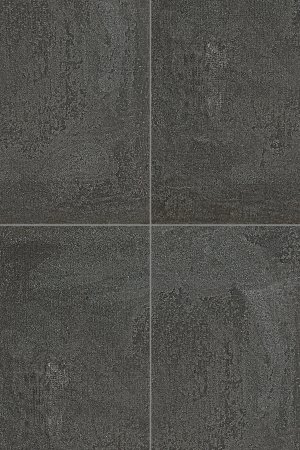

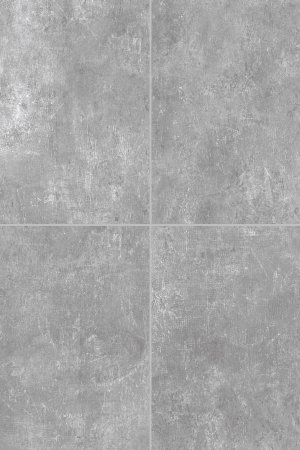

Designs

DRYTILING

Structure

DRYTILING

DryTiling

- Ceramic tile

- Cork backing

Technical data sheet

DRYTILING

| DryTiling | |||

| Dimensions & thickness | EN ISO 10545-2 | ca. 1203 × 603 × 11 mm |

| Classification | UNI EN 14411 / ISO 13006 | App. G B I a / Annex G B I a |

| Total weight | EN 430 | ca. 20 000 g/m² |

| Effect of castro chair | EN 425 | geeignet |

| Reaction of fire | EN ISO 9239-1 | Bfl s1 |

| Thermal resistance | EN 12524 | 0,068 m² K/W |

| Dimensional stability | EN 434 | < 0,02 % |

| Residual inentation | EN 433 | 0,00 mm |

| Lightfast | ISO 105 | > 7 |

| Emissions value | in conformity with AgBB | ||

| Swellness value 24h | EN 317 | 0% (waterproof) |

| Reaction to static electricity | EN 1815 | < 2,0 kV |

| Coefficent of friction | EN 51130 | R11 |

| Temperature resistance | Resistant | ||

| Joint width | ca. 3 mm | ||

| Impact sound reduction | 14 dB | |

| Resistance to chemicals | EN ISO 10545-13 | A-LA-HA |

| Resistance to stains | EN ISO 10545/14 | 3 / 3 / 3 |

| Abraison resistance | EN ISO 10545/6 | < 175 mm³ | |

| Breakage resistance | EN ISO 10545-4 | ≥ 35 N/mm2 (individual Min. 32 N/mm2) ≥1300 N | |

| Thermal expansion coefficient | EN ISO 10545/8 | 6,5 × 10 -6 / °C |